How Membrane Switches Are Used to Improve Safety and Performance in Machinery

How Membrane Switches Are Used to Improve Safety and Performance in Machinery

Blog Article

Why Membrane Switches Over Are Necessary for Resilient Control Systems

Membrane switches play an essential role in making certain the sturdiness and reliability of control systems throughout various markets. Their one-of-a-kind building permits them to sustain challenging ecological variables such as humidity, temperature level extremes, and physical wear. This strength not only prolongs the life-span of the systems they serve however additionally lessens maintenance demands. As we explore the diverse benefits of membrane layer buttons, it comes to be noticeable that their significance goes beyond simple functionality, affecting user experience and functional performance. What further implications do these features hold for the future of control system style?

Overview of Membrane Layer Switches

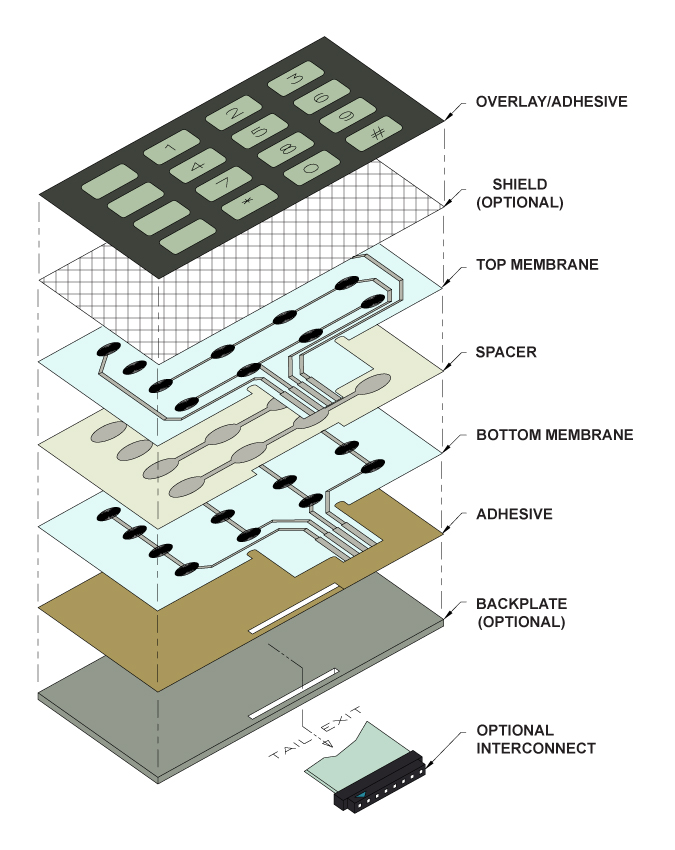

Membrane layer switches are functional and dependable parts frequently utilized in numerous digital control systems. These switches consist of numerous layers, consisting of a graphic overlay, a spacer layer, and a published circuit layer. The graphic overlay gives both functional and aesthetic design, while the spacer layer guarantees that the buttons are activated just when pressed. The printed circuit layer contains conductive traces that finish an electric circuit when the membrane is pressed, making it possible for the gadget to react to customer inputs.

Membrane buttons are commonly favored in applications calling for a small and light-weight design, making them suitable for handheld devices, clinical devices, and commercial machinery. They can be customized to fulfill specific customer needs and can include various attributes such as backlighting, tactile feedback, and several colors. Membrane switches are resistant to dirt, moisture, and contaminants, making them appropriate for atmospheres where longevity is essential.

Benefits of Resilience

In several applications, the durability of membrane layer changes offers considerable advantages that boost their general performance and dependability. These switches are developed to hold up against extreme environments, making them excellent for use popular problems such as high moisture, severe temperatures, and exposure to chemicals. Their robust construction assists to prevent damage from physical effect, making sure durable functionality and lessening the need for constant replacements.

Additionally, membrane layer buttons are immune to deterioration, which is essential in applications where constant communication occurs. This longevity translates to lower maintenance costs, as companies profit from decreased downtime and fewer solution interruptions. The encapsulated design of membrane changes shields interior components from dust and moisture ingress, additional adding to their lifespan (membrane switch).

An additional advantage is their ability to keep consistent efficiency with time. With a high tolerance for mechanical anxiety, these buttons preserve their responsive comments and electric stability, guaranteeing customer complete satisfaction. Eventually, the toughness of membrane switches over not only improves functional efficiency however also fosters confidence in their dependability, making them a favored selection for control systems throughout numerous markets.

Applications in Different Industries

Resilient control systems utilizing membrane buttons find extensive applications throughout a variety of sectors, each benefiting from the unique features these buttons provide. In the clinical field, membrane switches are crucial for gadgets such as patient monitors and diagnostic equipment, where integrity and ease of cleaning are extremely important. Their resistance to wetness and impurities guarantees they keep performance in sterile atmospheres.

The automobile industry leverages membrane layer buttons for control panel controls and infotainment systems, where they provide streamlined, low-profile user interfaces that enhance customer experience. These buttons are likewise created to endure harsh problems, consisting of exposure to extreme temperatures and resonances.

In industrial setups, membrane layer buttons are typically utilized in equipment control board, providing tactile comments and resilience essential for high-usage applications. Their capability to withstand chemicals makes them ideal for producing atmospheres where spills and pollutants are regular.

Consumer electronics, such as cooking area home appliances and push-button controls, additionally make use of membrane layer buttons for their versatility and cost-effectiveness. Generally, the Read Full Report versatility and durable nature of membrane layer switches make them essential throughout different markets, guaranteeing reliable operation and longevity in control systems.

Design and Visual Allure

While capability is critical, the layout and visual allure of control systems geared up with membrane layer switches play a critical duty in customer engagement and overall experience (membrane switch). The aesthetic style of these buttons can considerably affect individual assumption and interaction. A well-designed membrane layer button boosts the appearance of the tool, making it extra appealing to users and promoting a connection in between the customer and the item

Membrane switches over provide a lot of flexibility in style, allowing producers to personalize graphics, shades, and structures to align with brand name identification and product aesthetics. The usage of dynamic shades and unique patterns can attract focus, while responsive responses can strengthen the individual's interaction with the device. Additionally, the capability to incorporate LED indicators and backlighting find more info into the membrane switch style gives both useful and visual benefits, enhancing exposure and functionality in numerous environments.

Enhancing Customer Experience

Additionally, membrane buttons can be personalized to include visual user interfaces, enhancing use by offering info in a clear and user-friendly way (membrane switch). This modification can include symbols, tags, and shade coding that guide users through complicated functionalities effortlessly. Furthermore, their versatility enables combination in numerous environments, guaranteeing constant efficiency whether in industrial machinery or consumer electronic devices

The sturdiness of membrane buttons likewise plays a crucial function in user experience. By holding up against severe problems and navigate here extended usage, these buttons decrease the possibility of system failings, therefore advertising integrity and individual self-confidence. Inevitably, the critical usage of membrane changes not just raises performance but also significantly enriches user interaction with control systems, making them an important part in modern-day layout.

Verdict

Report this page